Automatic Channel Feeding System

SAMPLE AREAS

Feed ChannelGENERAL INFORMATION

The special design and is extremely handy with a wide mouth feed channel is made in galvanized steel is made from 1mm thick. (Channel length of 3 mt.)

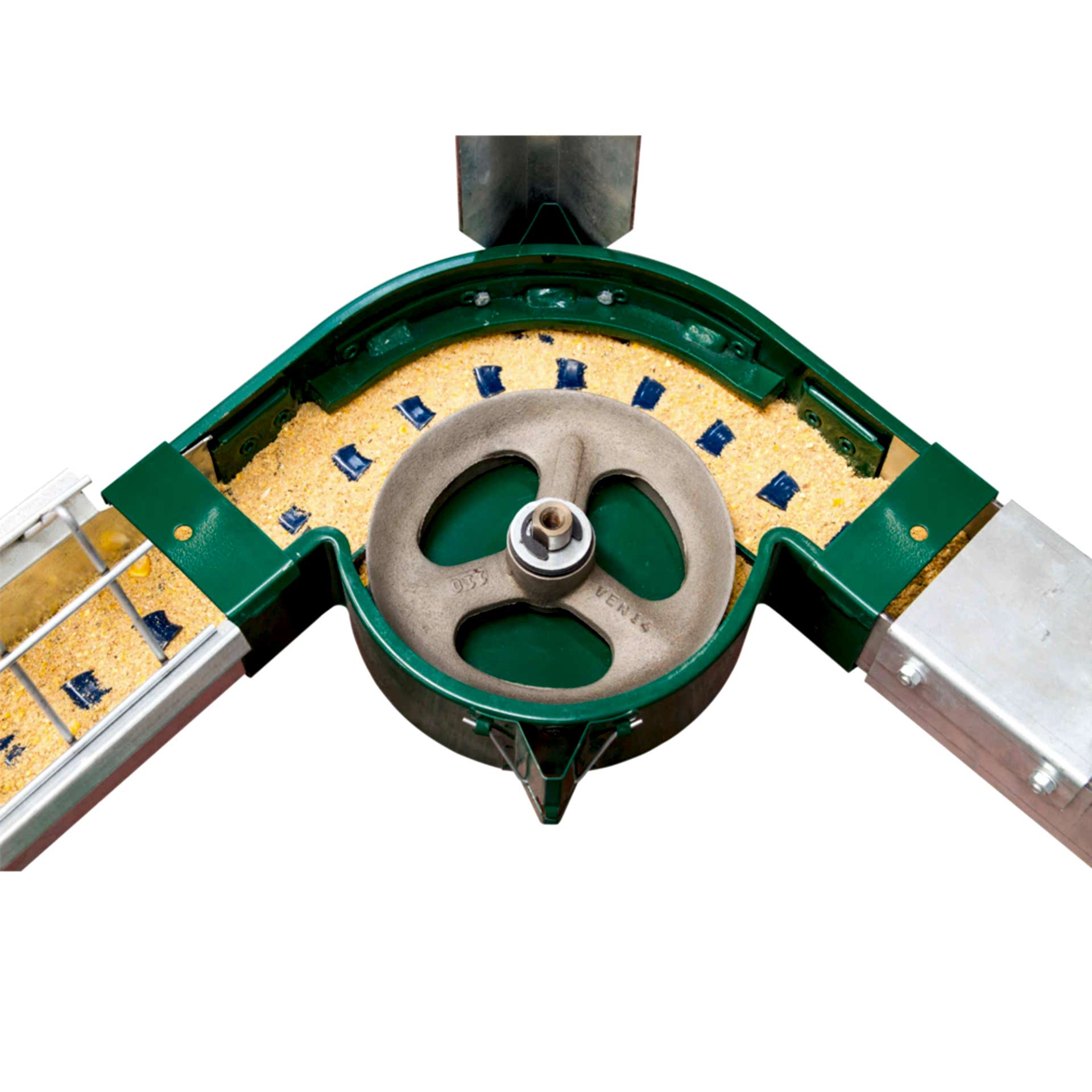

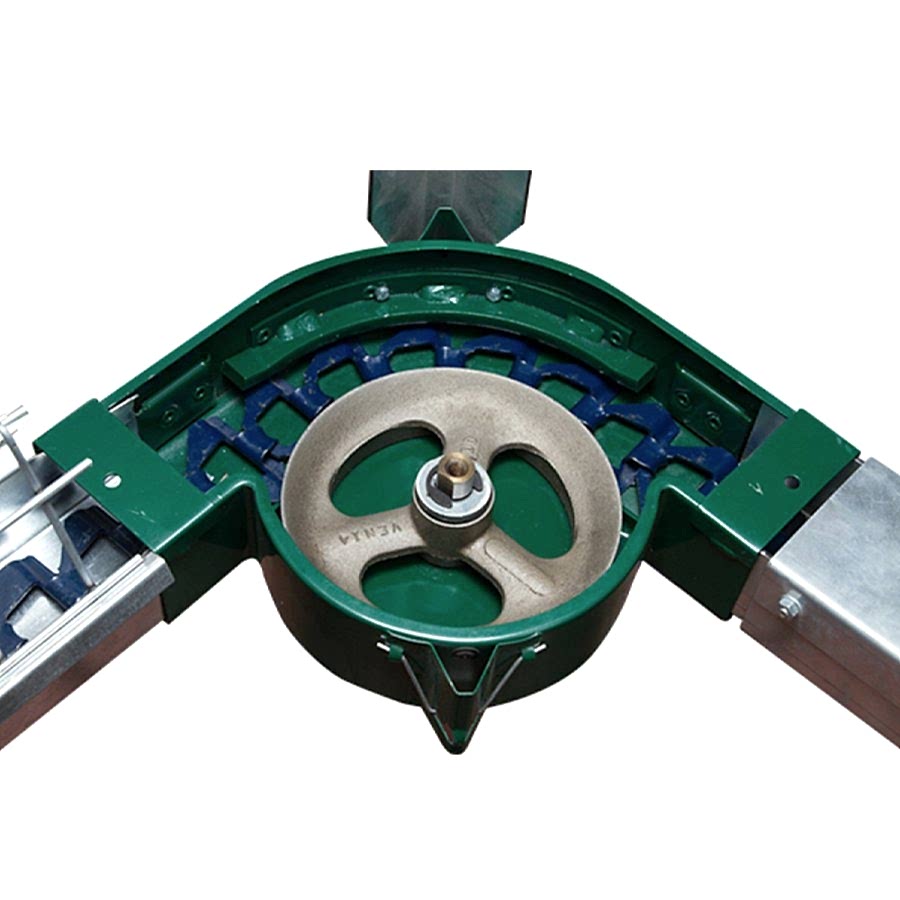

Feed Cornerit does not require any oil and maintenance, ductile iron castings and corner feed channel is one of the most important parts of the line. Even in 90 degree corner at high speed, manual work seamlessly with heat treated rails and self-lubricating bearings. it is still appropriate to the leg and lift-automatic feeder canal system. Height-adjustable feet and lifting lugs for connection system is available in both the hanging feeders.

Feed Chainmade of special materials in our chain, curling, lengthening, there is absolutely no space. It has a tensile strength of up to 12 kN. 2 as the kind you are sunulmış müşterilerimizint erhic. Corner and in harmony with the engine running gears. High-speed resistant.

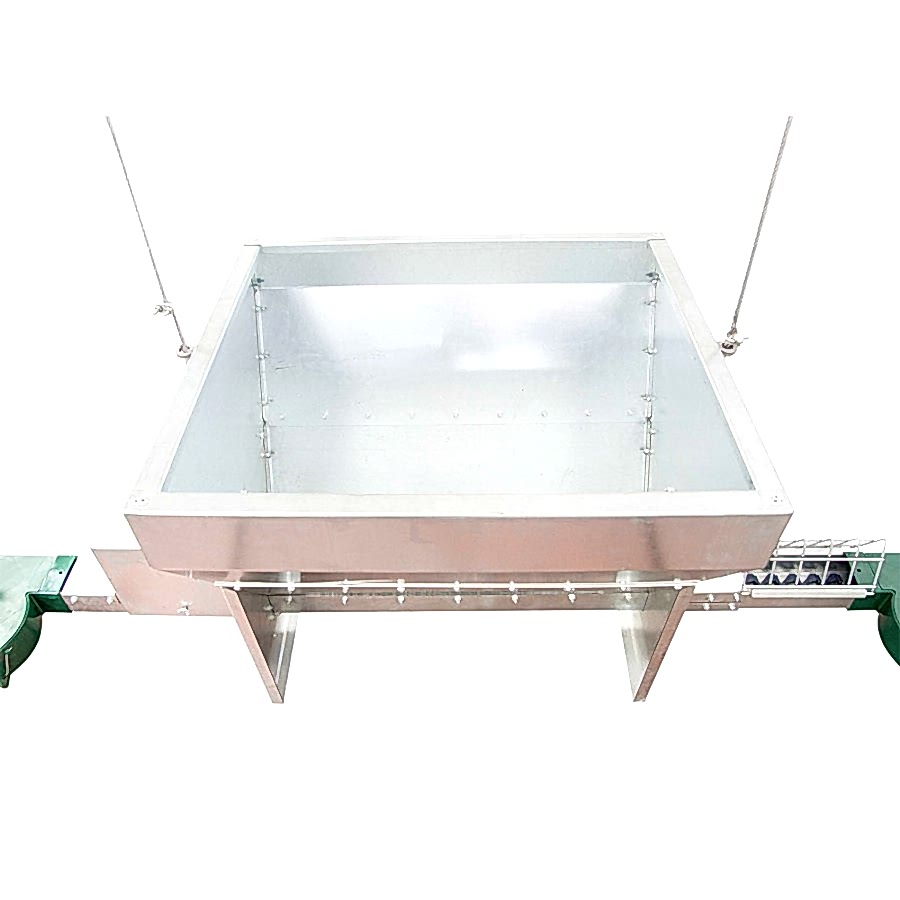

Channel Feed Removal SystemRemove the engine should be feeding systems, pulleys and steel ropes with scissors, working under the bridge channel hair is linked to the corners and tanks. The motor is geared brake and double-5d / d or reduce the speed of the transmission system convenient and slow to rope diameter 50 mm pipe with winding Amara. Reel sloping keep the balance between fixed and 4 beds wheels structures kestamit special ingredients to get the deflection. Up and down motion is set in kotnrol board.

GrillThe top grille channel is designed to provide an equal amount of animal feed and eat regularly. foot and lift the system does not vary. Wire system found on shock. Impact-resistant and does not stretch. According to the type of live grid spacing in the set are made in different sizes.

Motor GroupChannel Madiran mechanism which drives the feeding system. Motor group is connected to the gear system. Motor and move the gear chain connecting the shaft. as well as in accordance with the feed store must remove the system state and system manufacturing is done standing. My purpose in doing this way Instructional; Since it is thought to switch the system on legs or the feet of kaldırmalı kaldırmalı of not encountering any problems.

Motor Group and Gear System- The lift-automatic channel manger Single Cycle engine system used.

- Double Leg Cycle engine used in the automatic feed system channels.

silo product is the first entry in his unit to the feeding line. Oath after this point, the work is done from a special material even distribution chain takes place. deps feed bütüklüg capacity varies according to the farm. According to need more than one output option is available. Also standing in the feed store manger footed automatic channel system is manufactured in the lift-automatic feeding system and a leg strap. The same feed tank can be used in both systems. Capacity is between 240-600 kg.

Feed Channel feet and BridgeAuto-footed channel used in feeding system, height adjustable, galvanized pipe üreitl of hair from the hair (bridge) is 2mm thick. As foot system is compatible with the one to one, the lift channel feed system is used by attaching linkage.

Nest Boxgalvanized iron plate made with our body Gollum, Most tahdat portions of the pressing need of the animal. To prevent foot on board the night animals entering the nest, yukr is moving towards. In this way the animal can not do inside the entrance. So as to prevent the animal eğimlidr the top of the roost. Each gfolluk eye kapasiledir of 3-4 animals. In base (chip), on which the nest will prevent heat loss. Nest, is set in a secluded and dimly lit portion should be placed as possible.

Control PanelThe brand is switching Siemes materials used in ALFA's electrical panel. The outer casing of the Board, is detachable and can be re-mounting feature powder coated, allowing movement of the lift chain automatic feeder system akanl engine; Stipe channel start-pole single speed button for the feed system into action. In line engine lifting, running up and down the line. Control buttons allow movement up and down the line. The controls also masef up and down through safety switches is done automatically.